Larger air improvements each hour rate must be held up during the airlock, it should be least twenty air changes for each hour. It expels the contaminants entered from the surface simply.

This kind of airlock system is commonly used in Injectable producing amenities to make sure that air contaminants from exterior will not contaminate the item.

Move-by airlocks, also referred to as double-door airlocks or interlocking airlocks, are employed for the transfer of products or samples amongst adjacent cleanrooms with different cleanliness degrees.

The airlock’s reduced pressure draws in air within the surrounding rooms, making certain that any contaminants are trapped throughout the airlock or directed into specialised filtration systems, which include HEPA (Large-Effectiveness Particulate Air) filters, that cleanse the air before it really is recirculated or expelled.

Any detected problems should be instantly dealt with to avoid compromising the containment and cleanliness of adjacent locations.

-Interlocking system should be mounted in airlocks to avoid the opening of both of those doorway simultaneously.

There are lots of types of airlocks, Every single designed for unique contamination Regulate and containment needs. Down below are the commonest types Employed in GMP-compliant environments:

As It's really a general job that air moves from a place of increased strain in direction of the realm of decrease force.

One of several unsung heroes in these clean up rooms is the air lock. Think of it for a buffer zone that assists maintain the integrity of these managed environments when enabling personnel and products to maneuver out and in.

The anaerobic circumstances created with the airlock not merely greatly enhance flavor but in addition add to an extended shelf life for your personal fermented vegetables. Delight in your creations over an extended time period with out worrying about spoilage.

Aseptic environments: In amenities where by aseptic tactics are employed to forestall microbial contamination, bubble airlocks offer A vital barrier.

Choosing an ideal container to your vegetable fermentation is essential. Whether it’s a glass jar, ceramic crock, or devoted fermentation vessel, be certain it’s clean and absolutely free from any residues that may have an impact on the taste of one's ferment.

In granulation space create 10 Pa so when We're going to open up the door, clean air will here shift from airlock to granulation place and powders from granulation will not likely enter to airlock as a result of differential stress. In the identical way in corridor make ten Pa so when We are going to enter from corridor get more info the clear air from air glance will shift into the corridor.

The airlock must be integrated into the facility’s General cleaning routine, with protocols for program cleaning and emergency decontamination if contamination takes place.

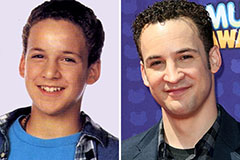

Ben Savage Then & Now!

Ben Savage Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!